Need A Restoration Quote?

Send Inspection Request

What is Roof Restoration?

Roof restoration (sometimes referred to as liquid roofing) is the process of renewing your existing roof to like-new condition with the use of elastomeric roof coatings. Restoring your roof does not typically require the removal or replacement of any existing material—aside from any small portions of the roof that may be damaged or compromised.

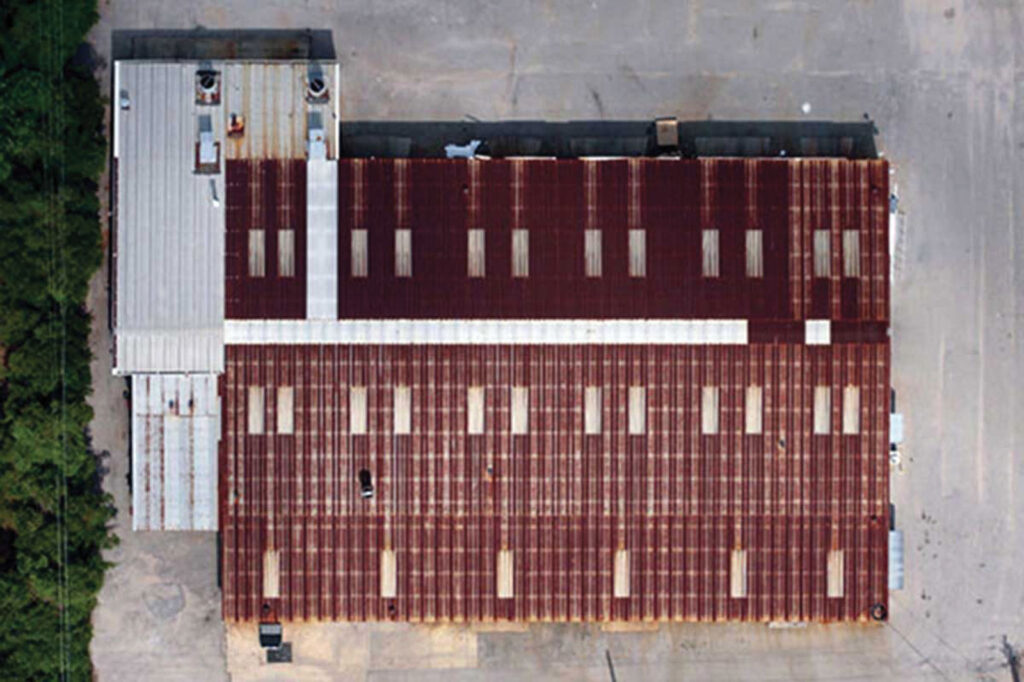

Before

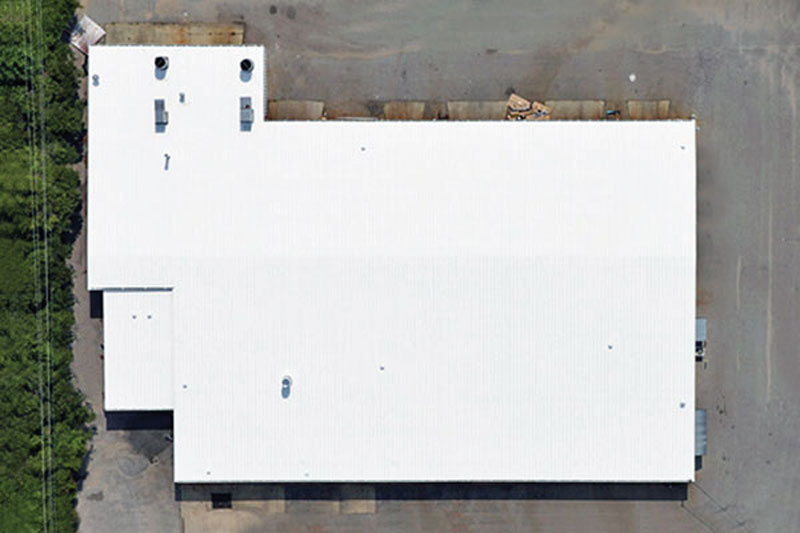

After

What Benefits Does Roof Restoration Provide?

Depending on the type of roof, a full replacement can cost anywhere from $7 to $20 per sq. ft. Restoration, on the other hand, provides all the advantages of a brand-new roof at a fraction of the cost. That’s because restoring a roof requires significantly less labor and material than conventional tear-off and replacement methods. As a result, you can expect to pay 30-50% less.

What Roof Types Qualify?

Many roof types can qualify for the restoration process, including: Metal, TPO, EPDM, BUR, MOD BIT, PVC, or Cement.

How Long Does a Restoration System Last?

Most commercial roof restoration systems are warranted to last anywhere from 10, 15, or 20 years. Beyond that, additional coatings are needed to sustain performance.

At What Point Should You Restore Your Roof?

The ideal roof restoration is implemented prior to the development of any issues. Day by day your roof is slowly degrading, making a proactive solution the recommended approach. The earlier in a roof’s lifespan a restoration system is installed, the more likely it is to perform successfully in the long term.

How Does the Installation Process Work?

The standard installation process can be broken down into four basic steps:

1. Surface Preparation

The first and most important step of the installation process is to pressure wash the existing roof to remove any dirt, dust, debris, or other foreign contaminants. This ensures the coating system will fully adhere to the underlying roof membrane.

Reduces Energy Costs

Unlike traditional roofing materials, the coatings that makeup restoration systems can reflect 80-90% of the sun’s UV radiation and diminish the transfer of heat to your building. This can drastically reduce system workload and cut interior cost by 20 percent.

2. Seams & Details

After surface preparation, all seams, transitions, penetrations, fasteners, drains, and other flashing details of the roof are coated with a thick waterproofing mastic. This enables the system to expand and contract (thermal movement) as temperatures fluctuate on the roof surface. It is important to address these components beforehand, as they are the most likely spots for leaks to occur.

More Sustainable

In recent years, the demand for more sustainable roofing solutions has grown considerably due to stricter environmental regulations and building codes, as well as a growing concern for the environment. Commercial roof replacements contribute millions of tons of waste to landfills annually. Restoration, however, requires no tear-off and has a minimal impact on the environment

3. Base Coat Application

Next, an elastomeric base coating is applied to the roof surface. This allows installers to build and maintain uniform mil thickness of the coating throughout the installation process.

4. Topcoat Application

Lastly, a topcoat application provides the system with UV stability and moisture protection. Most topcoats form a bright-white membrane that provides the optimal amount of reflectivity; however, they can be custom-tinted to a variety of colors.